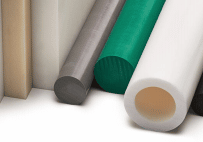

Engineering Plastic

Engineering Plastic Supplier

Natural Acetal

Acetal copolymer has an exceptional balance of tensile properties, shear strength, stiffness, and toughness. The toughness of this resin is evident in its high tensile yield strength. It is a natural bearing material because it exhibits a very low coefficient of friction against metals, and has excellent abrasion resistance. The thermal properties are unusually good. It has excellent resistance to high intermittent temperatures and it retains its shape and physical integrity at elevated temperatures. The long-term stability at high temperature is outstanding. Additional thermal characteristics are its excellent retention of initial mechanical properties in hot air and hot water.

Natural Nylon

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon is a thermoplastic silky material that can be melt-processed into fibres, films, or shapes. It is made of repeating units linked by amide links similar to the peptide bonds in proteins. Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibres (apparel, flooring and rubber reinforcement), in shapes (moulded parts for cars, electrical equipment, etc.), and films (mostly for food packaging).

Polyether Ether Ketone (PEEK)

Polyetheretherketone (PEEK) is a semi-crystalline, high-performance engineering thermoplastic. This rigid opaque (grey) material offers a unique combination of mechanical properties, resistance to chemicals, wear, fatigue and creep as well as exceptionally high-temperature resistance, up to 260°C (480°F). This polymer belongs to Polyketonefamily of Polymers (PEK, PEEK, PEEKK, PEKK, PEKEKK) and amongst them, PEEK is the most widely used and manufactured in large scale.

TUFNOL

TUFNOL is a proprietary brand of laminated plastic material. It has been made in Birmingham, England since the mid-1920s and is one of the pioneering types of resin bonded plastic materials used for engineering components.

Many people know of laminates as hard, thin sheet materials used for kitchen worktops, flooring and the like.

These are 'decorative laminates'. TUFNOL is an 'industrial laminate'. It does not have a specially coloured or patterned surface layer but it is made in big chunks as well as thin sheets, and these are used to make components for machinery and industrial purposes. It is usually brown to white in colour, depending on the grade, and can be made in solid sheets up to 225mm (9 inches) in thickness, and also in round rods and tubes

FAQs on Engineering Plastic

- strength and durability

- corrosion resistance

- dimensional stability

- electrical insulation design versatility

- cost-effectiveness

Engineering plastics are high-performance polymers formulated to offer superior strength, durability, and specific properties compared to standard plastics. They bridge the gap between traditional plastics and metals, providing a lightweight yet robust alternative for various industrial uses.

Engineering plastics, the power players of the plastics world, go beyond the limitations of standard plastics. These high-performance materials, also known as technical thermoplastics, boast exceptional mechanical, thermal, and chemical properties. This translates to superior strength, allowing them to handle demanding applications and outperform their everyday plastic counterparts.

Engineering plastics find themselves in a wide range of demanding industrial applications due to their impressive properties. Automotive parts, machinery components, piping and tanks, chemical processing equipment, marine applications, electrical components and more...