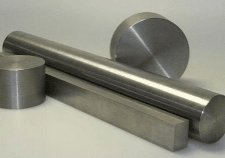

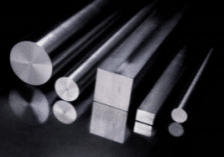

D2 Tool Steel

Local D2 Tool Steel Suppliers

Within the category of cold-work tool steels, a specific group known as "D steels" stands out for their high carbon and chromium content. This group encompasses D2, D3, D4, D5, and D7 steels, each containing roughly 1.5 to 2.35% carbon and a substantial 12% chromium.

While D2, D4, D5, and D7 steels all share the characteristic of air hardening and typically contain 1% molybdenum, D3 steel diverges slightly. It requires oil quenching for optimal hardening, although small sections can be gas quenched after austenitization using a vacuum environment. This unique hardening process can lead to increased brittleness in D3 tools compared to its air-hardening counterparts.

D2 steel reigns supreme as the most popular choice within the D group, prized for its exceptional performance and widespread applications.

Chemical Composition

The following table shows the chemical composition of D2 tool steels.

| Element | Content (%) |

| C | 1.40 – 1.60 |

| Mn | 0.60 |

| Si | 0.60 |

| Co | 1.00 |

| Cr | 11.00 – 13.00 |

| Mo | 0.70 – 1.20 |

| V | 1.10 |

| P | 0.03 |

| Ni | 0.30 |

| Cu | 0.25 |

| S | 0.03 |

Physical Properties

The physical properties of D2 tool steels are outlined in the following table.

| Properties | Metric | Imperial |

| Density | 7.7 x 1000 kg/m3 | 0.278 lb/in3 |

| Melting point | 1421°C | 2590°F |

Mechanical Properties

The mechanical properties of D2 tool steels are tabulated below:

| Mechanical Properties | Metric | Imperial |

| Hardness, Knoop (converted from Rockwell C hardness) | 769 | 769 |

| Hardness, Rockwell C | 62 | 62 |

| Hardness, Vickers | 748 | 748 |

| Izod impact unnotched | 77.0 J | 56.8 ft-lb |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30457 ksi |

D2 tool steel stands out within the D group for its exceptional wear resistance and impressive hardness achievable through a simple air hardening process. This high-carbon, high-chromium composition offers a well-balanced combination of toughness and affordability, making it a go-to choice for diverse cold work applications. Its minimal distortion during hardening ensures dimensional stability, while its moderate corrosion resistance adds a layer of protection in specific environments. D2's versatility and ease of heat treatment solidify its position as a top contender within the D steel family, offering a compelling blend of performance and practicality.