Aluminium Plate Suppliers and Stockholders

Aluminium Plate UK Grade 5083 is a high-strength, corrosion-resistant alloy primarily composed of magnesium, with trace amounts of manganese and chromium. It is widely used in marine applications due to its exceptional resistance to saltwater corrosion. Additionally, it offers excellent weldability and formability properties.

The Differences Between an Aluminium Plate & an Aluminium Tooling Plate

Aluminium plate and aluminium tooling plate are two different aluminium products with distinct characteristics and applications.

Aluminium plate and aluminium tooling plate, while sharing a similar appearance, are distinct aluminium products. Aluminium plate is manufactured through a rolling process, whereas tooling plate undergoes specialised treatments, such as casting or rolling, followed by additional processing to achieve exceptional flatness and dimensional stability.

Aluminium Plate:

Manufacturing Process: Rolled

Properties: Good general-purpose plate with moderate strength and machinability.

Applications: Diverse applications, including construction, signage, and general fabrication.

Aluminium Tooling Plate:

Manufacturing Process: Specialised treatments, such as casting or rolling, followed by additional processing for improved flatness and dimensional stability.

Properties: Exceptional flatness, dimensional stability, and machinability.

Applications: Precision engineering applications, such as tooling, jigs, fixtures, and moulds.

The Making of Aluminium Plate: A Rolling Marvel

An Aluminium plate is primarily produced through a process known as rolling. This involves heating a massive, pre-cast ingot of aluminium, often weighing 20 tons or more, to a specific temperature. This heated ingot, typically measuring around 6 feet wide, 20 feet long, and over 2 feet thick, is then fed into a powerful rolling mill.

The rolling mill gradually reduces the thickness of the ingot, shaping it into a long, flat sheet. This process can be repeated multiple times, with the ingot being reheated as needed to maintain optimal rolling conditions. Once the desired thickness is achieved, the sheet is cooled and further processed.

To enhance the strength and properties of the aluminium plate, various treatments may be applied. These include:

- Cold Rolling: This process involves rolling the plate at room temperature, increasing its hardness and strength.

- Heat Treatment: This involves heating the plate to a specific temperature, followed by rapid cooling. This process can significantly improve the mechanical properties of the aluminium, such as strength and ductility.

By carefully controlling these processes, manufacturers can produce a wide range of aluminium plate products tailored to specific applications, from construction and aerospace to automotive and marine industries.

The Applications of an Aluminium Plate

Plate aluminium, renowned for its strength and durability, finds extensive use in a variety of industries. Its applications range from heavy-duty sectors like aerospace, military, and transportation, where it is used to construct critical components for aircraft, vehicles, and ships. It is also employed in the manufacturing of cold storage tanks, demonstrating exceptional performance even in extremely cold conditions.

Thinner aluminium sheet, a versatile material, is utilized in a wide range of applications. It is commonly used in the production of beverage cans, packaging materials, car bodies, truck trailers, household appliances, and cookware. In the construction industry, the aluminium sheet is employed for roofing, cladding, siding, gutters, and carports, offering a combination of aesthetics and durability.

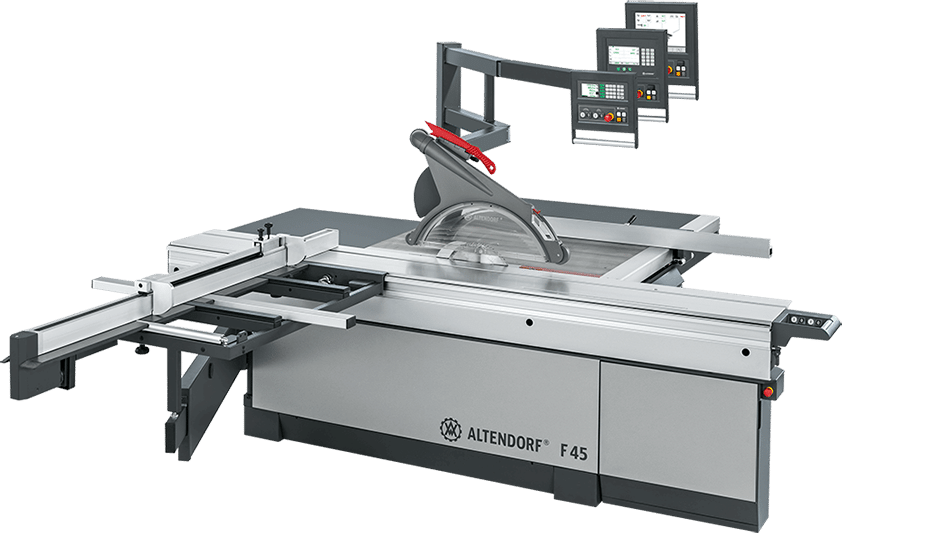

Aluminium Plate Cutting

An Aluminium Plate Saw is a specialised machine designed to cut through aluminium plates with precision. It utilises a large, circular TCT (Tungsten Carbide Tipped) blade to efficiently slice through the material. To protect the plate from damage during the cutting process, it is placed on an air bed, which provides a stable and cushioned surface. This machine is particularly well-suited for industrial and commercial applications, as it is capable of producing straight cuts and precise angles.

Colt Materials provides a cutting service so you can receive bespoke measurements for your projects. Order with us today- give us a call!

FAQS on Aluminium and its Qualities

Yes, aluminium is significantly lighter than steel. In fact, it's approximately one-third the weight of steel. This weight advantage translates into numerous benefits, including reduced transportation costs, improved handling, and enhanced structural efficiency. For instance, an aluminium sheet of a given size and thickness weighs considerably less than a steel sheet of the same dimensions.

Despite its lightweight nature, aluminium exhibits remarkable strength. When compared pound-for-pound, aluminium can even surpass the strength of steel and stainless steel. This exceptional strength-to-weight ratio makes aluminium an ideal choice for safety-critical components in various industries, such as aerospace, automotive, and cycling.

Unlike steel, aluminium does not rust. This is due to the absence of iron in its composition. While aluminium does oxidize, forming a protective oxide layer that prevents further corrosion, this process is significantly different from the destructive rusting of steel. This inherent resistance to corrosion eliminates the need for protective coatings, reducing maintenance costs and extending the lifespan of aluminium products.

While aluminium is generally more expensive than steel, it's often comparable in cost to stainless steel. However, the long-term cost-effectiveness of aluminium can surpass that of steel due to its superior corrosion resistance. By eliminating the need for protective coatings and reducing maintenance requirements, aluminium can offer significant savings over its lifespan.